The pandemic has wreaked havoc on innumerable elements of daily life – and industry is no different. Infected workforces, quarantines, and uncertainty have knocked back supply chains in almost every industry, and there’s currently global turmoil with electronics components supply chains.

So why exactly, and what can be done about it?

Why is there a shortage of IC components?

A huge amount of modern manufacturers rely on just-in-time production. That is, ordering raw materials just before running out in order to minimise costs on warehousing & storage. In an ideal, normal, world, this is a great way to cut costs, increase efficiency, and stop depreciation of raw materials through things like spoilage.

But when long supply chains rely on just-in-time methods, the smallest knock to that chain can cause serious problems.

Well, the pandemic has been much more than a small knock in the supply chain. But problems in sourcing raw materials and components (such as semiconductors) have been compounded with a dramatic increase in the demand for electronics. From August 2020-21, for example, there was a 30% increase in demand for copper foil.

Growing awareness of the devastating effects of climate change is fuelling a swift uptake in new technologies such as electric cars & renewables. In the meantime, technological innovations are resulting in a broad appeal for home and personal electronics like mobile phones, laptops, Alexa & Nest devices, and even doorbells!

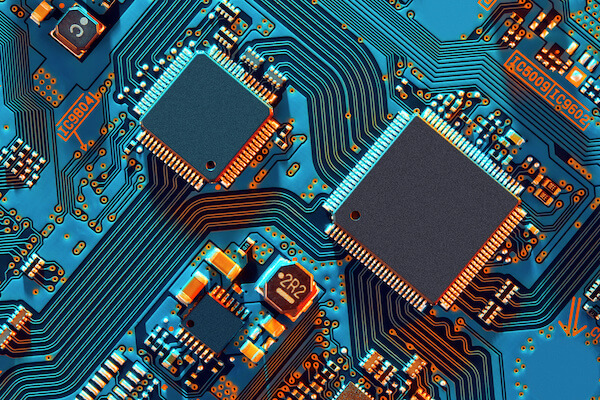

The smaller they get, the more appealing they become – that’s exactly what Integrated Circuit (IC) chips & PCBs enable.

Before PCBs & IC chips, electrical engineers would have to physically wire together all of the components – which is why older tech tended to be so bulky! In order to be produced effectively, all of these modern devices need PCBs and the components that make them work.

While there isn’t a shortage of every single IC component, there are disruptions in so many supply chains that it’s made getting hold of any vital equipment very difficult. What’s more, due to the growing demand, the components that are available are quickly snatched up by larger electronics producers. And any components that are left more widely available currently have dramatically extended lead times.

Frequently, producers are left with access to batches of components, but not enough to fully create whichever board they need.

It’s like having a lot of flour for cake, but no eggs or chocolate!

How have we prepared?

While our industry is much more niche, it hasn’t been less affected by the component shortage. However small, many of our water testing products rely on effective circuit boards to function – and our customers rely on our products to operate effectively.

After all, being able to accurately monitor water level & quality is vital for preserving waterways & wildlife as well as providing advanced flood warnings.

It’s just as vital, therefore, that our equipment stays available. So we frequently plan ahead and stock up to account for market and supply chain fluctuations. This time has been no different!

If you’re in need of water monitoring equipment, you can rely on Aquaread — even while IC components are in short supply. We’ve been able to keep our products available and proudly continue to stay ahead of the curve in what we offer.

So take a look at our water monitoring products here or browse by sensor type. If you have any questions about any of our products, their calibration, or the possible applications, don’t hesitate to get in touch with our friendly team.